The term “forklift ramp” can span a wide list of products all having the same function. That is to allow a forklift truck to travel across a space. Sometimes with a change in height relative to its starting point.

By this definition a curb ramp, dock board, rail board or yard ramp all qualify.

The length, width and capacity of each is determined by the job at hand. A curb ramp or dock board may be 3′ or 4′ long while a mobile yard ramp may be 30′ to 40′ or longer to allow for a forklift truck with it load to gain or loose the height difference between the ground and the loading dock or truck bed.

Forktruck ramps are essential pieces of equipment for any business that uses forklifts to move materials. They provide a safe and efficient way to load and unload goods from trucks, trailers, and other vehicles.

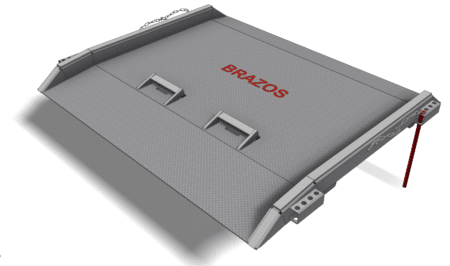

Brazos Manufacturing takes the description of the job and designs the product suited to safely do the work on a daily basis in real life conditions. While we have many different models of each type of forktruck ramp our designs can easily and economically be adjusted to be the perfect ramp for your job.

You can get a good idea of the specifications that fit your application by reading “HOW TO SPECIFY’. You can contact us today for a quick quote on the exact product for your job.