The controls on manufacturing quality are most often guaranteed by some sort of certification. When dealing with the fabrication of pressure vessels – the ASME certification is the “gold standard”. When dealing with the repair of pressure vessels – the “R” stamp is that standard.

ASME Certification means the manufacturer has implemented an ASME Quality Control System. Has submitted to inspections and auditing of all processes and systems involved in the manufacturer of pressure vessels. Continues to maintain standards and stand for ongoing inspections. These efforts are expensive and time consuming but assure the owners and operators of the stamped vessels, they are receiving a quality product.

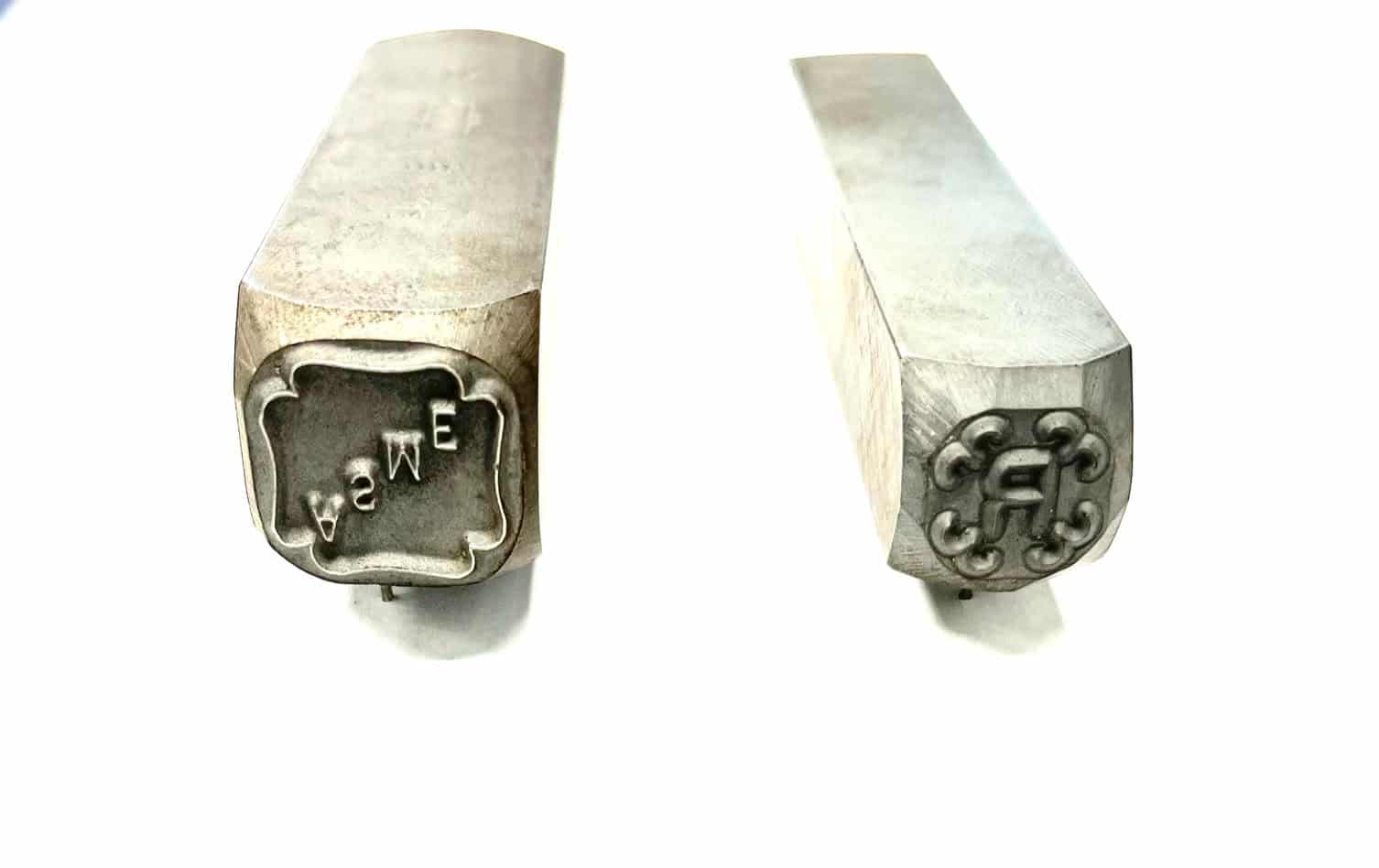

The “R” Stamp – The Department of Transportation requires any repairs on an ASME component — the shell or tank of a pressure vessel — to be performed by a welder in a qualified shop that has the R Stamp certification, which means the welder is certified by the National Board of Boiler and Pressure Vessel.

Brazos Manufacturing & Welding Services takes great pride in the fact that we hold both the ASME & R stamp. The quality assured by the disciplines of meeting those requirements spills over into all other endeavors. Including our Material Handling Equipment, Safety Equipment and all Energy verticals.