Dock Board Capacity – How to Specify

Dock Board Capacity. This is a “general” discussion about how to make the decision of which dockboard to specify in an application…regarding capacity.

For a Four Wheel Forklift Truck

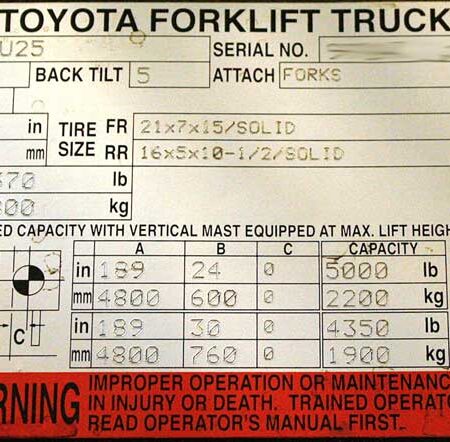

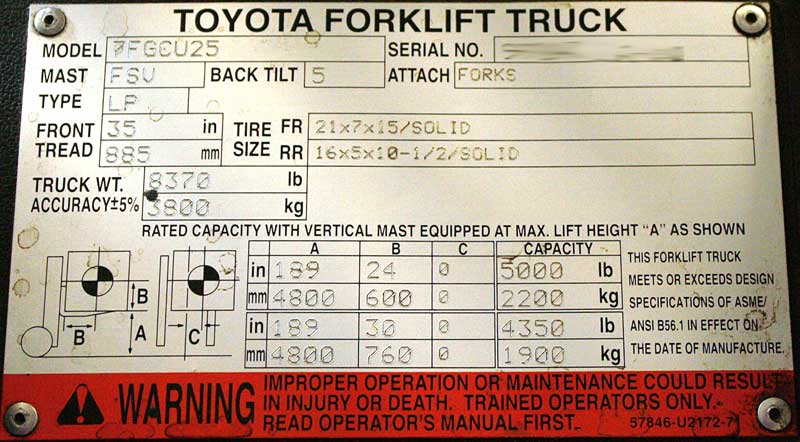

The rule of thumb is to take the capacity of the forklift truck and multiply it by three. This would apply if the operation is a light/medium duty application. This type of application would be a truck used in a single shift to load or unload several pallets per shift. As you can see in the dataplate here the weight of the truck is listed at 8,370 lbs. Add the capacity of the truck (also shown on the dataplate) of 5,000 lbs. You come up with 13,370 lbs not including operator and any other add-ons. A 15,000 lb capacity board would be indicated here. For multiple shifts or any unusual considerations you should upgrade to a 20,000 lb capacity unit.

For a Three Wheel Forklift Truck

When considering capacity of the dock board in using either a three-wheel forklift truck or a four-wheel where the steer wheels are inset (close to center of truck). You need to up the capacity from the starting calculations by an additional increment. The larger part of the weight bearing structure of a dockboard is at its edges (the curbs). Depending on the board’s design there may be additional substructure to help bear the weight but most will be on the edge. That results as the weakest part of the board being the center which is why a three-wheel forklift is problematic. So make all other calculations first and then increment up when considering the three wheel factor.

Forklift Capacity 5,000 lbs

X 3 for board 15,000 lbs

+ for high speed 20,000 lbs

+ for 3 wheel 20,000 lbs

When in doubt contact customer service at Brazos Manufacturing and let us help specify the exact board for you or your customers needs. For a discussion on dockboards or yard ramps.